CUTOMER SUPPORT & SALES

+ 91-9833297671 / 9819030056

+91-9833297671

INQUIRY NOW

for DOMESTIC – info@ravipharma.in

for INTERNATIONAL – exports@ravipharma.in

ROTARY VACUUM PADDLE DRYER

Rotary Vacuum Paddle Dryers is utilized in varied industries to extract and obtain dry powder either from solutions or wet cake. Operational efficiency is high and the costs incurred are low with this dryer when compared to other dryers in the market.

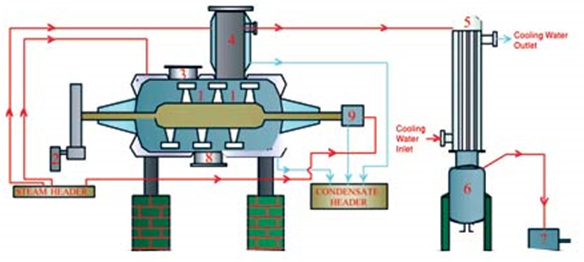

The mechanism, involves a closed system wherein hot water, steam, or hot fluid is used as a heating medium within the jacket, in the hollow paddle as well as in the hallow shaft. This paddle dryer includes vacuum pump, condenser, receiver and dust collection.

Wet feed receives good heat transfer with the constant agitation triggering heated rotating paddles and minimum clearance between scrapers and heated walls. This process gives rise to the evaporation of moisture or solvent, which makes the wet material dry to the essential level.

Vacuum is used to remove the vapors that are formed already. Further, the dust problems are eradicated with the absence of large air flows, which also results in low energy consumption.

These vacuum paddle dryer (RVPD) are highly appreciated in the market.

FLOW CHART OF ROTARY VACUUM DRYER :

FEATURES : | |

|

Rotary Vacuum Paddle Dryers (RVPD) is a cylindrical jacketed vessel with a central agitator having specially designed blades. The blades of this Rotary Vacuum Paddle Dryer (RVPD) are so designed that they sweep the entire internal surface and at the same time turn the material so that all the particles are come in contact with the heated surface. GMP construction – Cylindrical, horizontal vessel with flat welded rear cover and a hinged flat front door opening up over the entire vessel diameter. With the door open the internals of the machine are fully accessible for cleaning and inspection purposes All surfaces in contact with the product such as the vessel, rear cover, front door, agitator and vapor filter are heated, providing very efficient heat exchange. To provide for good heat exchange and discharge characteristics the cylindrical vessel, the rear cover, the front door and the agitator are machined to assure the smallest possible tolerances between agitator and vessel walls. The agitator is installed at the rear of the dryer, supported on one side of the vessel only. The agitator is designed to meet the requirements of this particular dryer type to assure good and even mixing action throughout the dryer volume, also in reverse operation. The agitator provides very good emptying characteristics, and at the same time reduces friction onto the product to a minimum to prevent local overheating as well as to prevent directional thrust or local product compression. A double mechanical seal is installed on the rear cover, well accessible for cleaning and maintenance purposes. A spacer in between the seal and the agitator drive permits removal of the seal without disassembling the drive. Dry or wet running mechanical seals may be installed. The central agitator shaft is supported on the one end bearings housed in bearing housing in such a way that the alignment remains always intact. This central agitator is driven by means of a Motor & Gear box through the bull Gear. The horizontal shell is jacketed to heat the shell with steam / hot water or any other thermal fluid. Limpet coil is provided instead of jacket if the heating media is fluid. A Dust Catcher consisting of bag filter is provided on the top to prevent the losses of material particles after the drying process. A Condenser of adequate heating surface area is provided wherein the evaporated vapors are condensed and these condensed vapors are then collected in the receiver of suitable capacity, placed beneath the condenser. A Vacuum Pump of adequate capacity is provided & fitted to the receiver of these rotary vacuum dryers to create the vacuum in the dryer shell through the Receiver, Condenser and Dust Catcher. | |

| SALIENT FEATURES OF ROTARY VACUUM DRYERS (RVD) : | |

|

TECHNICAL DATA : | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||