CUTOMER SUPPORT & SALES

+ 91-9833297671 / 9819030056

+91-9833297671

INQUIRY NOW

for DOMESTIC – info@ravipharma.in

for INTERNATIONAL – exports@ravipharma.in

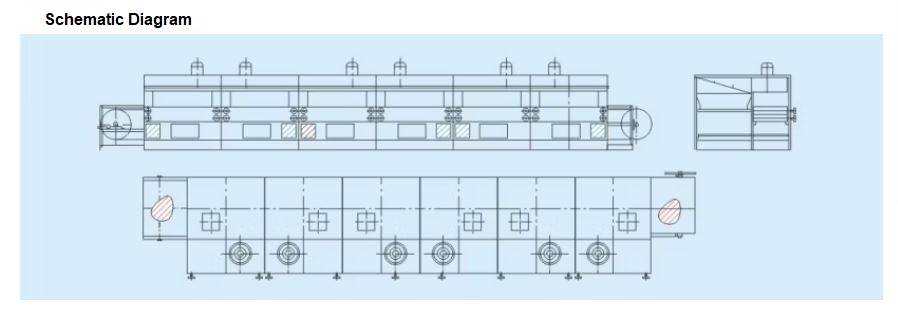

CONTINUOUS BELT DRYER

____________________________

- Large Capacity

- 24-hour Continuous Operation

- Good Drying Effect

- Static Drying

- No Damage to Material Appearance

- Energy Conservation

- Environment Protection

Brief Introduction :-

RAVI – Continuous Belt Dryer is a drying equipment for continuous production, which is used for drying flaky, strip and granular materials with good air permeability. It is especially suitable for dehydrated vegetables, catalysts, and other materials with high water content and low/high material temperature.

Continuous Belt Dryer is series of dryers have the advantages of fast drying speed, high evaporation intensity and good product quality. For the paste materials of dehydrated filter cake, they can only be dried after granulating or making into strips. The raw materials can be medicine raw materials, Bulk drug, food items, dairy products, fertilizers, pesticides, paint, powder, granule, packing bottle, pigment, dyestuff, dehydration vegetable, dried fruit and melons, banger, plastic resin, electric elements, drying varnish and so on.

Continuous belt Dryer, has the advantages of high drying rate, high evaporation intensity and good product quality. Belt dryer is widely used in industry, mainly for drying small pieces of materials and fibrous materials. In a word, the materials dried by the belt dryer must have a certain shape, and still keep a certain shape after drying.

Working Principle :-

The material is evenly spread on the mesh belt by the feeder, and the mesh belt adopts 12-60 mesh stainless steel mesh. Driven by the transmission device, it moves in the dryer. The dryer is composed of several units. Each unit has an independent hot air circulation. Part of the tail gas is discharged by a special dehumidification fan. The waste gas is controlled by a regulating valve. The hot gas passes through the materials laid on the mesh belt from bottom to top or from top to bottom, and is heated and dried to take away the moisture.

The net belt moves slowly, the running speed can be adjusted freely according to the material temperature, and the dried product falls into the collector continuously. The upper and lower circulation units can be flexibly equipped according to the needs of users, and the number of units can be selected according to the customers’ needs.

Features :-

- Low energy consumption: No heat carried out by the air due to indirect heat. There’s no heat insulation layer with the exterior wall of the dryer. It consumes 1.2kg steam to evaporate 1kg water for drying slurry materials.

- Low cost of the blade dryer system: the unit effective volume has a large heat transfer surface, so the processing time is shorted; the size of the equipment becomes small. It greatly reduces the floor area and building space.

- Handling wide range of materials: Heat sensitive material and the materials to be processed under high temperature might be processed with different heating media.

- Common media are: steam, thermal oil, hot water and cooling water, etc.

- Continuous operation or intermittent batch operation, widely used in many fields.

- Environmental pollution is less: Without any carrying air, very few powders is carried out. Evaporation of the solvent material is very small, easy to handle. For the materials that might cause pollution or the solvent to be recovered, it might adopt sealed circulation.

- Stable operation: the wedge-shaped blades will do special compression, expansion of stirring effect, the material particles will fully contact with the heat transfer surface in the axial section. The difference of the temperature, humidity and mixing effect are very small in the different axial area, so to ensure the stability of process.

- Low speed will not break the granular materials or sliced materials.

TECHNICAL SPECIFICATIONS : CONTINUOUS SINGLE BELT CONVEYOR

Model | BD-RV1.2×8 | BD-RV1.2×10 | BD-RV1.6×8 | BD-RV1.6×10 | BD-RV2x8 | BD-RV2x12 |

Unit number | 4 | 5 | 4 | 5 | 4 | 6 |

Belt width | 1.2m | 1.2m | 1.6m | 1.6m | 2m | 2m |

Drying system length | 8m | 10m | 8m | 12m | 8m | 12m |

Thickness of material | 10~80mm | |||||

Temperature | 50~140ºC | |||||

Steam pressure | 0.2~0.8Mpa | |||||

Steam consumption | 120~300kg | 150~375kg | 150~375kg | 170~470kg | 180~500kg | 225~600kg |

Drying strength | 4~20kgm2/h | |||||

Power of blower | 3.3Kw | 4.4Kw | 6.6Kw | 8.8Kw | 12Kw | 16Kw |

Power of equipment | 4.05Kw | 5.15Kw | 7.35Kw | 9.55Kw | 13.1Kw | 17.1Kw |

Note : We also have multi-layers model, and our dryer is non-standard, can be customized according to the actual requirements, if you are interested, please feel free to contact us.