CUTOMER SUPPORT & SALES

+ 91-9833297671 / 9819030056

+91-9833297671

INQUIRY NOW

for DOMESTIC – info@ravipharma.in

for INTERNATIONAL – exports@ravipharma.in

MULTI BELT DRYER

CONTINUOUS MULTI BELT DRYER :

- Large Capacity

- 24-hour Continuous Operation

- Good Drying Effect

- Static Drying

- No Damage to Material Appearance

- Energy Conservation

- Environment Protection

RAVI – Multi Belt Dryer machine is a continuous working drying equipment. Belt dryer is used for drying pieced materials, sliced materials, strips, and granular materials with good ventilation.

Especially suitable for the materials which have high water content and works without high temperature, such as dehydrated vegetables, herbal medicines of traditional indian medicines, etc.

Can also dry paste material of de-watering filtering cakes after being made into granules or slices.

Multi Belt Dryer widely used in pharmacy, chemical, food stuff, plastic products, gum, electron, de-watering vegetable, additive, gourmet powder, shredded coconut stuffing, organic color, compound rubber, acryl fiber, medicine, medical material, small wooden product, aging and solidification of the electronic components.

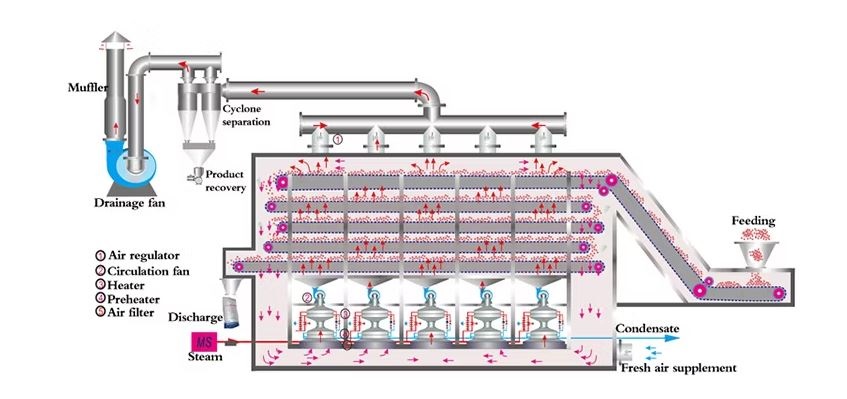

Working Principle :-

The Multi Belt Dryer, belt is sized at 12-60 mesh, made of stainless steel wire screen. The materials are put on the belt by the feeder, and continuously moves from one side to the other side inside the dryer by a transmitting device.

Composed of several units with separate circulating hot air. Some exhausted air is discharged from a special moisture-discharging blower. The waste air is controlled by a valve. The hot air passes through the belt from the top to the bottom or from the bottom to the top to complete the process of transferring and exchanging heat and mass, and takes out the moisture inside the raw materials. The circulation units can be freely equipped according to customers demand.

- The speed of the belt can be freely adjusted as per the heating temperature of the materials.

- The number of drying units can be customized according to request.

- Air pressure and air volume can be adjusted.

- Drying temperature and drying area can be controlled.

- We can add necessary auxiliary equipment and use different process to meet different characteristics of raw materials.

CONTINUOUS MULTI BELT DRYER :

1. Heating room: It is a space for installing electric heating equipment and generating hot air. The fan is installed in an appropriate position. The fan is forced to circulate the air to make the temperature difference between the upper and lower sides of the dryer small. The unique adjustable air separation perforated plate ensures a uniform temperature.

2. Hot air conveying mode: The circulating fan sends hot air to the hot air passage, and then enters the material chamber through the porous air dividing plate, and adopts the air supply mode of the upper, lower, left and right sides to make the drying more uniform.

3 Heating equipment: electric heating, coal burning, gas, steam, etc. (heating source can be selected). The machine has reasonable structure, convenient installation, and maintenance, stable operation, simple use, long service life, low operating cost.

4. Ventilation and moisture removal equipment: The equipment is divided into three types: bottom ventilation, side ventilation, and top ventilation. It can be designed and manufactured according to different materials and plant requirements and equipped with a powerful wind direction communication system to make the airflow of the entire drying room sufficient. Temperature control and humidity control in the drying box ensure the proper temperature for drying, step control of drying time, real automation management, and equipped an alarm system.

Features :-

- The air volume, heating temperature, material residence time, and feeding speed can be adjusted to achieve the drying effect.

- The equipment configuration is flexible, and the belt washing system and material cooling system can be used.

- Most of the air is recycled, which saves energy.

- The double-layer air circulation structure is adopted, the hot air is even, and there is no partial dry phenomenon.

- According to the characteristics of the material, different process flow and additional auxiliary equipment can be added.

- Fast-drying speed and high evaporation intensity.

- The mesh belt has good gas permeability and the drying cycle can be arbitrarily adjusted.

- According to customer needs, it can be divided into several units; each unit can control the loop separately.

- There are various heat source selections, such as steam heating, electric heating, heat transfer oil heating, hot air heating, etc.

CONTINUOUS MULTI BELT CONVEYOR

Models | MBD/RV-1.2×8 | MBD/RV-1.2×10 | MBD/RV-1.6×8 | MBD/RV-1.6×10 | MBD/RV-2×8 | MBD/RV-2×10 |

Area of dry(m²) | 9.6 | 12 | 12.8 | 16 | 16 | 20 |

Drying section length×belt width (m) | 1.2×8 | 1.2×10 | 1.6×8 | 1.6×10 | 2×8 | 2×10 |

Quantity of unit | 4 | 5 | 4 | 5 | 4 | 5 |

Temperatureof operation (ºC) | 50-150 | |||||

Pressure of steam (Mpa) | 0.2-0.6 | |||||

Consumption of steam (Kg/h) | 120-250 | 150-375 | 150-375 | 170-470 | 225-600 | 450-1200 |

Drying time (h) | 0.2-1.5 | 0.25-1.5 | 0.2-1.5 | 0.25-1.5 | 0.2-1.5 | 0.25-1.5 |

Evaorating capacity (Kg/H2O) | 60-160 | 80-220 | 75-220 | 95-250 | 100-260 | 120-300 |

Power(kw) | 11.4 | 13.6 | 11.4 | 13.6 | 19.7 | 11.77 |

Overall dimension (L×N×H)m | 9.8×1.5×2.8 | 11.8×1.5×2.8 | 9.8×2.5×2.8 | 11.8×2.5×2.8 | 9.8×2.65×3.50 | 11.8×2.65×3.50 |

Weight (Kg) | 4800 | 5780 | 5400 | 6550 | 6350 | 7800 |

Note :

We also have non-standard multi-layers model, can be customized according to the actual requirements, if you are interested, please feel free to contact us.