CUTOMER SUPPORT & SALES

+ 91-9833297671 / 9819030056

+91-9833297671

INQUIRY NOW

for DOMESTIC – info@ravipharma.in

for INTERNATIONAL – exports@ravipharma.in

CONTINUOUS FLUIDIZED BED DRYER

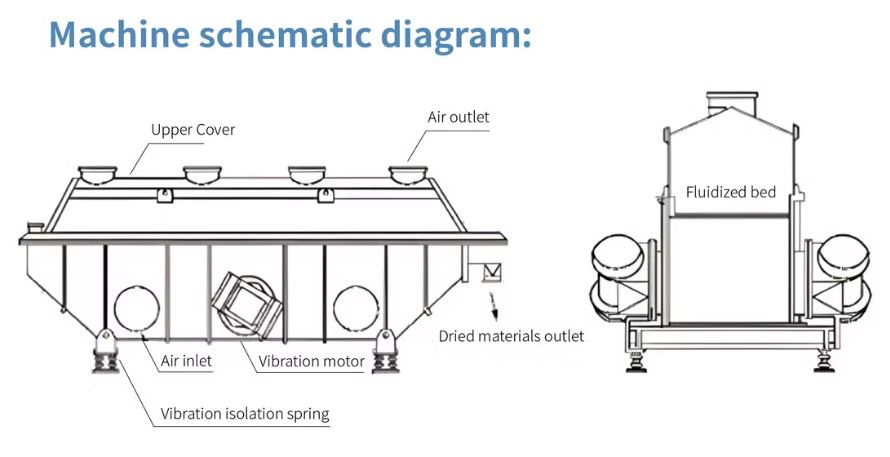

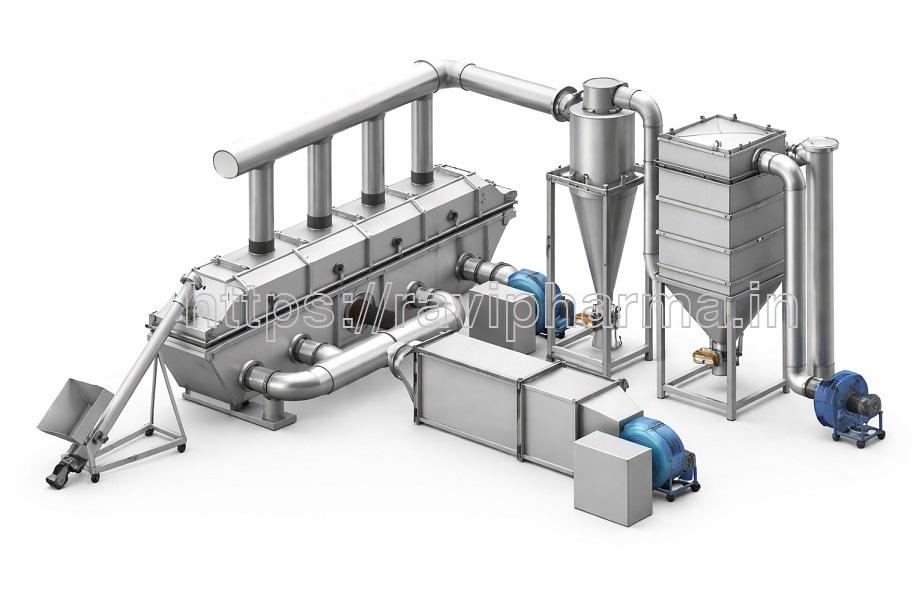

Introduction & Applications :- RAVI – Continuous Fluidized Bed Dryer is a kind of intensified drying device with special purpose. It is usually used for the final drying of materials. As the material fluidization is assisted by mechanical vibration in the drying process, it is not only beneficial to the boundary layer turbulence and the enhancement of heat and mass transfer, but also ensures the drying equipment to work under the relatively stable flow mechanical conditions. This equipment has a good drying function, but also according to the needs of the process with material cooling, screening and conveying processes.

RAVI – Continuous Fluidized Bed Dryer is designed for continuous drying of non-sticky particles. Cold air is filtered, heated, and then distributed through the bed’s perforated plate, flowing upwards. Materials enter the bed via a screw feeder or belt Conveyor, move forward due to vibration (vibrating motor to produce excitation force to make the machine vibrate), the material jumps forward under the action of this excitation force in the given direction, while the hot air is input at the bottom of the bed to make the material in fluidized state, the material particles are in full contact with the hot air and carry out intense heat and mass transfer process, at this time the highest thermal efficiency. The upper cavity is in the state of micro-negative pressure, the wet air is led out by the induced fan, and the dry material is discharged from the discharge port, so as to achieve the ideal drying effect. If cold air or wet air is sent to the bottom of the bed, it can achieve cooling and humidifying effect. These dryers are utilized for drying, cooling, and humidifying powders in industries such as pharmaceutical, bulk drug, chemical, food, fertilizer, plastic, grain and oil, slag, salt, and sugar.

CONTINUOUS FLUIDIZED BED DRYER :

Principle :-

Raw material is fed into the drier from the inlet and moves forward continuously along with the level of fluidized bed under the vibrating force. The hot air passes through the fluidized bed and exchange heat with wet raw material and become wet air. The wet air will exhaust out after passing cyclone separator and dust collector. The dried material will discharge from the outlet automatically.

Features :-

- Vibrating source is driven by vibrating motor, with smooth operation, easy maintenance, low noise, long service life and convenient maintenance.

- The mechanical efficiency and thermal efficiency are high, and the energy saving effect is good, which can save 30-60% energy than the general drying device.

- Uniform temperature distribution prevents overheating and ensures even fluidization.

- Adjustable material layer thickness, machine speed, and vibration amplitude for versatile applications.

- Minimal damage to material surfaces, suitable for drying delicate or irregularly shaped particles.

- Fully enclosed structure prevents contamination, keeps the environment clean, and supports continuous operation.

- Multiple units can be linked for large-scale production of high-moisture materials.

It can be used for drying fragile material because of the small damage to the material surface.

Technical Specifications:-

Model (L×W) | Area of fluidized-bed | Temperature of inlet air | Temperature of outlet air | Capacity Tons / hr | Capacity of vaporizing moisture | Vibration motor |

RV-CVFBD 3000 × 300 | 0.9M3 | 70~140ºC | 40~70ºC | 1.5-2 | 20~35kg/hr | 0.75kw × 2 |

RV-CVFBD 4500 × 300 | 1.35M3 | 70~140ºC | 40~70ºC | 2-3 | 35~50kg/hr | 0.75kw × 2 |

RV-CVFBD 4500 × 450 | 2.025M3 | 70~140ºC | 40~70ºC | 3-4 | 50~70kg/hr | 1.1kw × 2 |

RV-CVFBD 4500 × 600 | 2.7M3 | 70~140ºC | 40~70ºC | 4-5 | 70~90kg/hr | 1.1kw × 2 |

RV-CVFBD 6000 × 450 | 2.7M3 | 70~140ºC | 40~70ºC | 4-5 | 80~100kg/hr | 1.5kw × 2 |

RV-CVFBD 6000 × 600 | 3.6M3 | 70~140ºC | 40~70ºC | 5-7 | 100~130kg/hr | 1.5kw × 2 |

RV-CVFBD 6000 × 750 | 4.5M3 | 70~140ºC | 40~70ºC | 7-9 | 120~140kg/hr | 2.2kw × 2 |

RV-CVFBD 6000 × 900 | 5.4M3 | 70~140ºC | 40~70ºC | 9-12 | 140~170kg/hr | 2.2kw × 2 |

RV-CVFBD 7500 × 600 | 4.5M3 | 70~140ºC | 40~70ºC | 7-9 | 130~150kg/hr | 2.2kw × 2 |

RV-CVFBD 7500 × 750 | 5.625M3 | 70~140ºC | 40~70ºC | 10-12 | 150~180kg/hr | 2.2kw × 2 |

RV-CVFBD 7500 × 900 | 6.75M3 | 70~140ºC | 40~70ºC | 12-16 | 160~210kg/hr | 3.7kw × 2 |

RV-CVFBD 7500 × 1200 | 9M3 | 70~140ºC | 40~70ºC | 18-22 | 200~260kg/hr | 3.7kw × 2 |

RV-CVFBD 7500 × 1500 | 11.25M3 | 70~140ºC | 40~70ºC | 23-28 | 260~320kg/hr | 5.5kw × 2 |