Introduction to Sterile Ointment & Cream Manufacturing Plant

GMP Compliant Pharmaceutical Equipment

In the pharmaceutical and cosmetic industry, sterile ointment and cream production requires precision, hygiene, and consistent quality. RAVI International specializes in designing high-performance, Sterile ointment & cream manufacturing plant that meet international GMP and FDA standards.

Our systems ensure zero contamination, smooth emulsification, and repeatable batch production – essential for topical pharmaceutical formulations and cosmetic creams.

Why Choose Sterile Ointment & Cream Manufacturing Plant?

Sterile ointment production is crucial for:

- Preventing microbial contamination

- Ensuring product safety and stability

- Meeting GMP and WHO standards

- Maintaining consistent viscosity and texture

- Improving shelf life and efficacy

With RAVI’s sterile manufacturing equipment, manufacturers can achieve efficient, hygienic, and scalable production for ointments, creams, and gels.

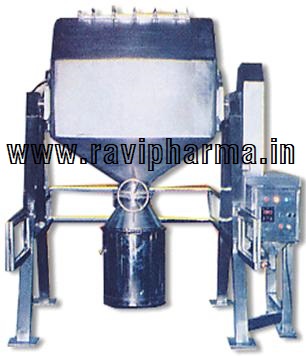

Core Components of RAVI Sterile Ointment & Cream Manufacturing Plant

Our plants are designed for complete sterile processing with the following key components:

1. Wax / Oil Phase Vessel

- Jacketed SS316 for uniform heating

- Hygienic design with mechanical seal agitators

- CIP/SIP compatible for easy sterilization

2. Water Phase Vessel

- High-efficiency heating for water-soluble ingredients

- Vacuum and temperature-controlled operation

- Sanitary design to prevent contamination

3. Main Ointment / Cream Vessel

- High-speed homogenizer for perfect emulsification

- Anchor agitator with Teflon scrapers

- Vacuum operation for air-free, smooth ointments

4. Interconnecting Piping & Transfer Pumps

- SS316L sanitary piping with zero dead legs

- Vacuum/pressure transfer system for contamination-free processing

5. Optional Inline Homogenizer

- Reduces particle size

- Enhances smoothness and product consistency

- Ideal for dermatological and pharmaceutical creams

6. Control System & Accessories

- PLC/HMI digital control panel

- Explosion-proof and automated options

- Temperature, vacuum, and agitation monitoring

Sterile Ointment & Cream Manufacturing Process

Step-by-step process workflow:

- Oil & Water Phase Preparation:

Ingredients are prepared and heated in dedicated vessels. - Phase Mixing:

Oil and water phases are combined under controlled temperature and vacuum. - Homogenization:

High-shear mixing ensures uniform particle size and smooth texture. - De-aeration:

Vacuum removes entrapped air for improved consistency. - Cooling & Final Mixing:

Maintains optimal viscosity while preventing contamination. - Transfer to Filling Line:

Finished sterile ointments are moved hygienically to automatic or semi-automatic filling machines.

Key Features of RAVI Sterile Ointment & Cream Plant

- GMP-compliant sterile design

- SS316/SS316L construction for hygiene and durability

- Vacuum homogenization for air-free products

- CIP/SIP compatibility

- Energy-efficient jacket heating and cooling

- Custom capacities from 50L to 10,000L

- Automation options for production efficiency

Applications

Our sterile ointment and cream manufacturing plant is ideal for:

- Pharmaceutical ointments and creams

- Antiseptic and dermatological formulations

- Cosmetic creams, gels, and lotions

- Moisturizers and skincare products

- Haircare and specialized topical solutions

Why RAVI International?

RAVI International provides turnkey solutions for sterile ointment and cream production, including:

- Expert engineering and design

- Long-lasting SS316L machinery

- Complete technical support, installation, and commissioning

- Validation services (DQ/IQ/OQ/PQ)

- Custom solutions for unique formulations

Conclusion

For pharmaceutical companies and cosmetic manufacturers aiming for hygienic, high-quality, and consistent ointment and cream production, RAVI Sterile Ointment & Cream Manufacturing Plant delivers unmatched reliability, performance, and regulatory compliance.

Contact RAVI International today to upgrade your sterile manufacturing capabilities and achieve zero contamination, efficient production, and superior product quality.