An automatic ointment cream manufacturing plant is a facility designed to produce ointment and cream products on a large scale, using automated machinery and equipment. The plant is typically designed to handle the entire manufacturing process, from mixing and blending of ingredients to filling and packaging of finished products.

An auto. ointment cream manufacturing plant is a complex system that involves a range of processes, including mixing, heating, cooling, and filling, all of which must be carried out with precision to ensure consistent quality and safety of the final product. Here are some of the key components and processes involved in an auto ointment/cream manufacturing plant :

- Mixing and Homogenizing: The first step in the manufacturing process involves mixing and homogenizing the raw materials, which can include oils, waxes, emulsifiers, and other ingredients. This is typically done using high-speed mixers and homogenizers that ensure a consistent and uniform blend.

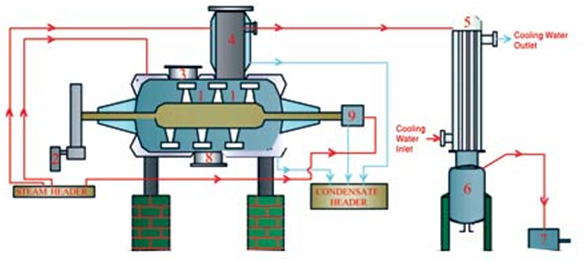

- Heating and Cooling: After the mixing process, the mixture must be heated to a specific temperature to ensure the proper consistency and texture of the final product. This is typically done using heating jackets or steam coils. Once the mixture is heated, it is then cooled to a specific temperature using cooling jackets or cold water.

- Filling: Once the mixture has been heated and cooled to the appropriate temperature, it is then transferred to a filling machine, which fills the ointment/cream into tubes or jars. The filling machine must be able to accurately dispense the product and seal the containers to prevent contamination.

- Cleaning and Sterilization: To ensure the safety and quality of the final product, the manufacturing plant must be regularly cleaned and sterilized. This involves the use of specialized cleaning agents and high-temperature sterilization equipment.

- Quality Control: Throughout the manufacturing process, the ointment/cream must undergo rigorous quality control testing to ensure that it meets the necessary standards for safety, consistency, and effectiveness. This typically involves testing for purity, viscosity, and other key properties.

Overall, an auto. ointment/cream manufacturing plant is a highly specialized system that requires advanced equipment, skilled operators, and rigorous quality control measures to ensure the production of safe, effective, and consistent products.

Email: For detailed inquiries or quotes, email us at: raviinternational01@gmail.com

Phone: Speak to a representative directly by calling: 91-9819030056

Online Form: Fill out below contact form for a quick response, and we’ll get back to you within 24 hours.