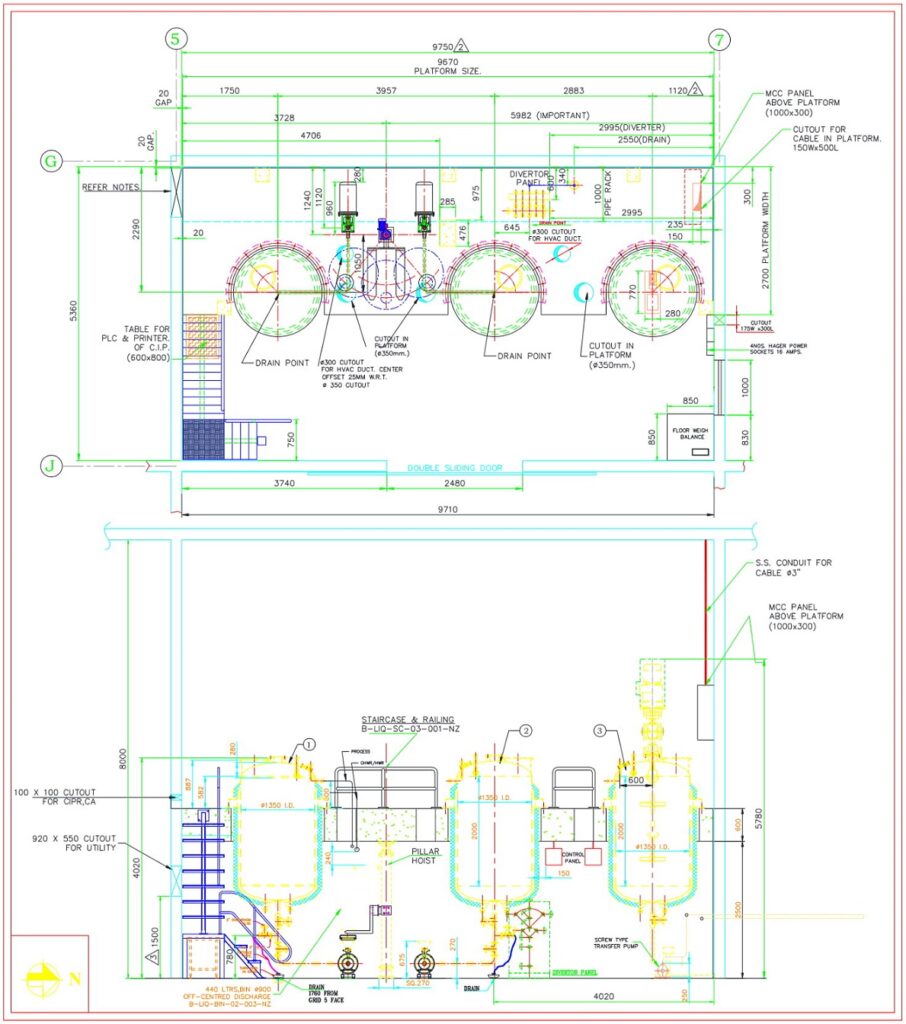

Automatic Liquid Syrup Manufacturing Plant is the perfect option for pharmaceutical oral preparations.

The plant is available with capacities ranging from 500 L to 2000 L. The plant is segmented into three main parts accompanied with transfer and filtration units for easy and smooth operation. watch video

Liquid Syrup Manufacturing Plant is the perfect option for pharmaceutical oral preparations.

The plant is available with capacities ranging from 500 L to 2000 L. The plant is segmented into three main parts accompanied with transfer and filtration units for easy and smooth operation.

Syrup Manufacturing Plant consists the following equipment and accessories.

- Sugar Syrup Vessel

- Online Sugar Syrup Prefilter

- Manufacturing Vessel

- Filtration unit (Sparkler type Filter Press)

- Inline Homogeniser (Micronizer)

- Storage Vessel

- Control Panel

- Product Piping

- Working Platform

Capacity Available : 500Ltrs. – 15000Ltrs.

Salient Features :

- The Plant is designed to be operated only by one operator and one helper.

- All material transfers are done by vacuum or by transfer pumps.

- All the vessels are cGMP (paint free construction)

- The gaskets used are of silicon (food grade).

- All contact parts are of SS316 quality material & finished to class 4B (Mirror) finish and are crevice free.

- Entry of all Propeller agitators / Homogenizer are from bottom through specially designed cartridge mechanical seal with TC / TC seal face.

- The advantage of Bottom entry agitators over conventional one is that there are no vibrations of shaft, no couplings in the drive assembly, excellent mixing technique & lower maintenance cost.

- All vessels are suitable for internal pressure of 1 Kg. / Sq. cm. and hence can be sterilized.

- All pipes, pipe fittings and valves are of SS304 / SS316 ( as per customer requirement ) seamless quality, internally electro polished,with tri-clover ended joints.

- The entire plant is equipped with CIP & SIP connections, so that customer can use these facility, if have CIP & SIP equipment.

- All values of temperature & time of the plant are indicated digitally on the control panel. Ampere indicates on Ampere meters.

- A micro processor based automatic operating plant can be designed as per requirement. (Optional ) All the inlet & outlet connections are provided with triclover joints, which are very easy for cleaning & replacement.

Email: For detailed inquiries or quotes, email us at: raviinternational01@gmail.com

Phone: Speak to a representative directly by calling: 91-9819030056

Online Form: Fill out below contact form for a quick response, and we’ll get back to you within 24 hours.