An Agitated Nutsche Filter Dryer (ANFD) is a type of filtration equipment used for solid-liquid separation and drying of the filtered cake. The working principle of an ANFD involves the following steps:

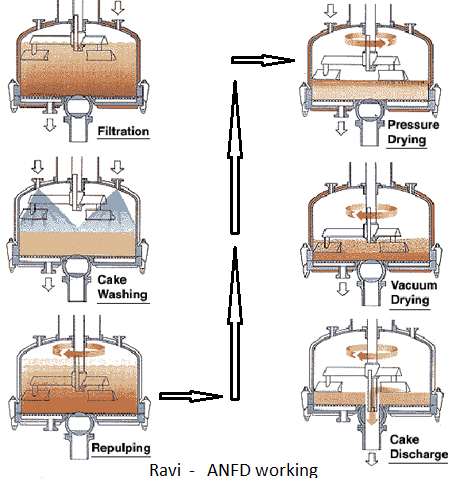

- Feed and Filtration: The slurry or liquid-solid mixture to be filtered is fed into the ANFD through a feed inlet. The filter medium (usually a porous filter cloth or screen) allows the liquid to pass through while retaining the solid particles to form a filter cake on the filter medium.

- Washing: Once the filtration is complete, the filter cake is washed with a suitable solvent or liquid to remove any remaining impurities.

- Drying: After washing, the filter cake is dried using either a vacuum or a combination of vacuum and heated air. The agitation of the filter cake during the drying process helps in breaking up the lumps and ensuring uniform drying.

- Discharge: Once the drying is complete, the dry cake is discharged from the filter using either a scraper or a pneumatic or hydraulic piston.

Agitated Nutsche Filter Dryer (ANFD) is a type of filtration equipment used in the pharmaceutical, chemical, and food industries for solid-liquid separation, washing, and drying of solids. The working principle of ANFD involves a combination of mechanical agitation and vacuum filtration.

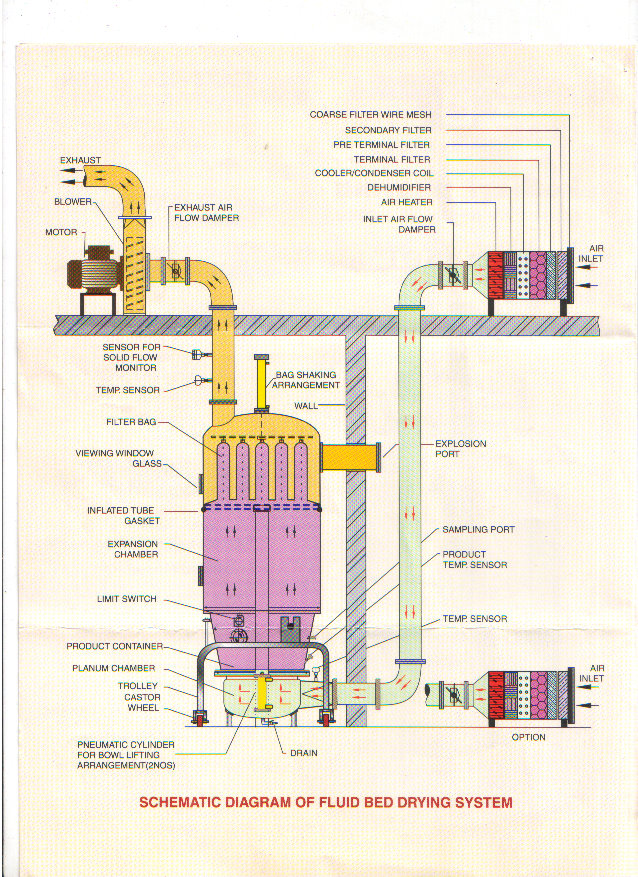

The ANFD consists of a cylindrical vessel with a flat bottom that acts as a filter bed. The filter is made up of a porous filter medium, typically a sintered metal mesh, supported by a mesh screen. The vessel is equipped with a stirrer that agitates the filter cake and a vacuum system that applies vacuum pressure to the vessel to aid in the filtration and drying process.

The ANFD operation begins by filling the vessel with the slurry containing the solids and the liquid to be separated. The stirrer is then turned on, and the filter cake begins to form on the filter medium. The vacuum system is then activated, which creates a pressure differential across the filter medium. This pressure difference causes the liquid to be drawn through the filter medium and into the vessel’s hollow shaft, leaving behind a dry cake on the filter medium.

The agitator continues to stir the filter cake, which helps to expose any remaining liquid trapped in the cake, aiding in the drying process. Once the filtration and drying are complete, the stirrer is stopped, and the filter cake is discharged from the vessel.

Overall, the ANFD’s working principle combines mechanical agitation, vacuum filtration, and drying to achieve a highly efficient solid-liquid separation, washing, and drying process.

The ANFD can be operated in a batch or continuous mode and is commonly used in the chemical, pharmaceutical, and food industries for the separation and drying of solids from liquids.

Email: For detailed inquiries or quotes, email us at: raviinternational01@gmail.com

Phone: Speak to a representative directly by calling: 91-9819030056

Online Form: Fill out below contact form for a quick response, and we’ll get back to you within 24 hours.