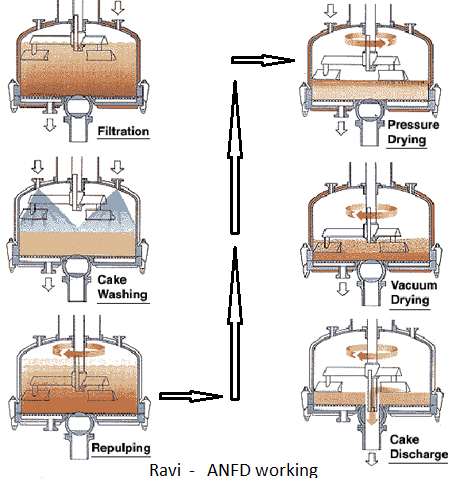

Ravi International – Principle & working of ANFD – Agitated Nutsche Filter Dryer (ANFD) is a type of equipment used for separating solids from liquids and drying wet materials. The principle of ANFD involves the use of a filter medium, typically a sintered metal filter or a filter cloth, to separate the solid particles from the liquid.

The ANFD consists of a cylindrical vessel with a perforated bottom, a filter medium that is attached to the bottom of the vessel, and an agitator that is used to mix and dry the material. The wet material is fed into the vessel and is mixed by the agitator, which creates a slurry.

Once the mixing is complete, the slurry is then filtered through the filter medium, which separates the solid particles from the liquid. The filtered liquid is then discharged from the vessel, leaving behind the solid particles on the filter medium.

The agitator is then used to dry the solid particles by removing any remaining moisture. The agitator can be heated to aid in the drying process, and a vacuum can be applied to the vessel to reduce the boiling point of the liquid, thereby speeding up the drying process.

In summary, the principle of ANFD involves mixing wet materials using an agitator, filtering the slurry through a filter medium to separate the solid particles from the liquid, and then drying the solid particles using the agitator and heat. The ANFD is a versatile equipment that can be used in a wide range of industries, including pharmaceuticals, chemicals, food, and biotechnology.

Construction of ANFD

Agitated Nutsche Filter Dryer (ANFD) is a specialized piece of equipment used in the pharmaceutical, chemical, and food industries for solid-liquid separation, washing, and drying of materials. ANFD consists of a vessel with an agitator, filter, and drying system. The construction of ANFD typically involves the following components:

- Vessel: ANFD is made of a cylindrical vessel with a conical bottom. The vessel is usually made of stainless steel or other corrosion-resistant material. The vessel is designed to withstand high pressure and vacuum, which allows the filtration, washing, and drying operations to be carried out under controlled conditions.

- Agitator: ANFD is equipped with an agitator that rotates at a high speed to create a uniform and thin cake of the material on the filter surface. The agitator is typically a blade or paddle that is attached to a rotating shaft that passes through the center of the vessel.

- Filter: ANFD has a filter system that separates the solids from the liquids. The filter is usually a perforated plate or wire mesh that is mounted on the vessel’s bottom. The filter is designed to withstand high pressure and vacuum, and it can be easily removed for cleaning and maintenance.

- Discharge System: ANFD also has a discharge system that removes the filtered cake from the vessel. The discharge system is typically located at the bottom of the vessel and is equipped with a valve that controls the flow of the material.

- Drying System: ANFD has a drying system that dries the filtered cake. The drying system is usually a jacket or external heating source that heats the vessel and the filter. The temperature can be controlled to meet the drying requirements.

- Vacuum System: ANFD can be operated under vacuum to reduce the boiling point of the material and facilitate faster drying. The vacuum system includes a vacuum pump that is connected to the vessel through a duct that evacuates the air from the vessel.

Overall, ANFD is a complex piece of equipment that requires careful design and construction to ensure efficient filtration, washing, and drying of materials.

principle and Working of ANFD

Agitated Nutsche Filter Dryer (ANFD) is a multi-purpose equipment used for solid-liquid separation, washing, and drying of various chemicals, pharmaceuticals, and food products. The ANFD has a cylindrical vessel with a perforated plate at the bottom and a stirrer inside the vessel. The working of ANFD involves the following steps:

- Loading: The slurry or wet cake is loaded into the vessel through the top manhole.

- Filtration: The slurry is then agitated by the stirrer, which creates a vacuum below the filter media. The liquid is filtered through the filter media and collected in the vessel.

- Washing: After filtration, the solid cake is washed with a suitable solvent or liquid to remove any impurities or residual product.

- Drying: After washing, the stirrer is used to dry the solid cake by applying heat or vacuum. The solvent is evaporated, leaving behind a dry solid cake.

- Discharging: Once the drying is complete, the dry cake is discharged from the vessel through the bottom discharge valve.

The ANFD offers several advantages over other types of filters, including high filtration efficiency, minimal product loss, reduced processing time, and a closed system, which eliminates the risk of product contamination. The equipment is also easy to clean and maintain, making it a popular choice for various industrial applications.

Uses of ANFD

Agitated Nutsche Filter Dryer (ANFD) is a type of equipment that is commonly used in the pharmaceutical, chemical, and food industries for various applications. Here are some of the uses of an Agitated Nutsche Filter Dryer:

- Solid-Liquid Separation: ANFD is commonly used for separating solids from liquids. It can be used for separating solids from a variety of liquids such as suspensions, slurry, and solutions.

- Filtration: ANFD can be used for the filtration of fine particles from the liquid. It is ideal for filtering particles that are difficult to filter with conventional methods.

- Drying: ANFD is an effective drying equipment that is commonly used for drying of wet cakes or slurry. It can be used for drying heat-sensitive or temperature-sensitive materials.

- Washing: ANFD can be used for washing of solids to remove impurities. It is ideal for washing of fine particles that are difficult to wash with conventional methods.

- Crystallization: ANFD can be used for crystallization of solids from the liquid. It can be used for crystallization of heat-sensitive or temperature-sensitive materials.

- Reactor: ANFD can be used as a reactor for various chemical reactions. It can be used for reactions that require high agitation and heating.

Overall, ANFD is a versatile equipment that can be used for a range of applications. Its ability to handle a variety of materials, high agitation, and heating, make it an ideal equipment for various industries.

Advantages of ANFD

The agitated nutsche filter dryer (ANFD) is a versatile piece of equipment that combines the functions of filtration, washing, and drying in a single unit. Some of the advantages of using an ANFD include:

- Efficient and time-saving: ANFDs can process large volumes of material in a relatively short time. The combination of filtration, washing, and drying functions in a single unit eliminates the need for multiple pieces of equipment, reducing processing time and increasing productivity.

- High product quality: ANFDs provide excellent separation and washing of solids, ensuring that the final product is of high quality with low residual moisture content. The ANFD design also minimizes the risk of product contamination.

- Cost-effective: ANFDs are cost-effective in terms of equipment investment and operational costs. The use of a single unit for filtration, washing, and drying reduces capital expenditures and operating costs, such as labor, energy, and maintenance.

- Safe operation: ANFDs are designed with safety in mind. The unit is completely sealed, minimizing the risk of exposure to hazardous or toxic materials. The use of an agitator ensures that the solids are well mixed, minimizing the risk of hotspots and ensuring uniform drying.

- Easy to clean: ANFDs are designed for easy cleaning and maintenance. The unit can be disassembled quickly, and the interior can be easily accessed for cleaning and inspection. The ANFD design also minimizes the risk of product buildup, reducing the need for frequent cleaning.

Overall, the ANFD is a highly efficient and versatile piece of equipment that can provide many benefits to a variety of industries, including pharmaceuticals, chemicals, and food processing.

Disadvantages of ANFD

Agitated Nutsche Filter Dryers (ANFDs) are commonly used in the pharmaceutical, chemical, and food industries for solid-liquid separation, washing, and drying of products. However, they do have some disadvantages, including:

- Cost: ANFDs are generally more expensive than other types of filters and dryers due to their complexity and unique design.

- Maintenance: ANFDs require regular maintenance to ensure their efficient operation. This can be time-consuming and costly.

- Product Loss: ANFDs have a relatively high hold-up volume, which means that there is a risk of product loss during operation. This can be a significant disadvantage for high-value products.

- Operator Safety: ANFDs can be hazardous to operate due to the presence of high-pressure steam and the potential for explosion if not operated correctly.

- Scale-up Challenges: Scaling up ANFDs from lab-scale to production scale can be challenging due to the complex design and the need for customized equipment.

- Material Compatibility: ANFDs may not be suitable for all types of materials due to their susceptibility to corrosion or other chemical reactions. This can limit their use in certain applications.

- Environmental Impact: ANFDs require a significant amount of energy to operate, which can contribute to greenhouse gas emissions and other environmental impacts.

Email: For detailed inquiries or quotes, email us at: raviinternational01@gmail.com

Phone: Speak to a representative directly by calling: 91-9819030056

Online Form: Fill out below contact form for a quick response, and we’ll get back to you within 24 hours.