A roto cone vacuum dryer is a type of industrial dryer that uses a combination of rotation, vacuum, and conical shape to efficiently dry materials. The dryer consists of a cone-shaped vessel that rotates on its axis, with a heating jacket on the outside and a vacuum pump connected to the interior. The cone shape and rotation of the vessel allow for efficient mixing and tumbling of the material being dried, while the vacuum helps to remove moisture by lowering the boiling point of water.

During operation, the material to be dried is loaded into the vessel, and the dryer is sealed and evacuated to create a low-pressure environment. The vessel is then heated, either with hot water or steam, to a temperature that evaporates the moisture from the material. The rotation of the vessel helps to prevent clumping and ensures that all parts of the material are exposed to the heat and vacuum.

Roto cone vacuum dryer is commonly used in the pharmaceutical, chemical, and food processing industries for drying powders, granules, and other materials that are sensitive to high temperatures and require a gentle drying process. They are known for their efficiency, versatility, and ease of operation, and are often used in conjunction with other equipment such as mills, sifters, and feeders to create a complete drying and processing system.

Rotocone vacuum dryer application

Roto Cone Vacuum Dryers are widely used in the pharmaceutical, chemical, and food processing industries for drying heat-sensitive materials, powders, and granules. Here are some specific applications of Roto Cone Vacuum Dryers:

- Pharmaceutical Industry: Used for drying Active Pharmaceutical Ingredients (APIs), intermediates, and final drug products. They are also used for drying antibiotics, vitamins, and other heat-sensitive materials.

- Chemical Industry: Used for drying chemicals such as organic and inorganic chemicals, dyestuffs, and pigments.

- Food Industry: Used for drying food products such as spices, herbs, vegetables, and fruits. They are also used for drying dairy products like milk, whey, and cheese.

- Agricultural Industry: Used for drying agricultural products like grains, seeds, and nuts.

- Environmental Industry: Used for drying sludge and wastewater from industries and municipalities.

- Textile Industry: Used for drying textile materials such as cotton, silk, and wool.

In summary, Roto Cone Vacuum Dryers are versatile and can be used for drying a wide range of materials across various industries.

Working principle of Rotocone vacuum dryer

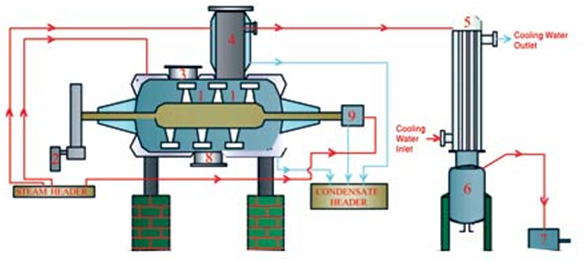

The Roto Cone Vacuum Dryer is a specialized drying machine used to dry materials that are sensitive to high temperatures or require gentle drying. The dryer consists of a conical vessel with a rotating shaft that has several mixing blades attached to it. The vessel is mounted on a hollow shaft that allows for the circulation of a vacuum or low-pressure gas through the vessel, which helps to evaporate the moisture from the material being dried.

The working principle of the Roto Cone Vacuum Dryer is based on the principle of indirect heating. The dryer is equipped with a heating jacket that surrounds the conical vessel. Heat is transferred to the material being dried through the conduction of the vessel walls. The vessel is rotated at a slow speed to ensure that the material is evenly mixed and exposed to the heating surface.

During the drying process, a vacuum or low-pressure gas is introduced into the vessel. The low-pressure environment lowers the boiling point of the liquid in the material being dried, facilitating its evaporation. As the material is rotated and mixed, the evaporated moisture is removed from the vessel through the vacuum system. The vacuum system also helps to reduce the oxygen content inside the vessel, which can prevent oxidation of the material.

Overall, the Roto Cone Vacuum Dryer is an efficient and gentle drying method that can handle a wide range of materials, including heat-sensitive or fragile substances.

Roto cone vacuum dryer advantages and disadvantages

Roto cone vacuum dryers are commonly used in the pharmaceutical, chemical, and food industries for drying powders, granules, and other materials. Here are some of the advantages and disadvantages of using a cone vacuum dryer:

Advantages:

- Faster drying: Cone vacuum dryers are designed to provide uniform and fast drying of materials due to their conical shape and rotating mechanism.

- Reduced oxidation: The vacuum environment in the dryer reduces the risk of oxidation and degradation of sensitive materials.

- Energy-efficient: The vacuum environment allows for lower drying temperatures, resulting in energy savings.

- Less space required: Roto cone vacuum dryers have a compact design, which makes them suitable for small production areas.

Disadvantages:

- High initial investment: The cost of purchasing and installing a roto cone vacuum dryer is high compared to other drying technologies.

- Maintenance: The rotating mechanism requires regular maintenance to ensure smooth operation and prevent wear and tear of components.

- Limited capacity: Roto cone vacuum dryers have a limited capacity, which may not be suitable for large-scale production.

- Potential product contamination: If the dryer is not properly cleaned and maintained, there is a risk of product contamination, which can lead to product recalls and loss of revenue.

Email: For detailed inquiries or quotes, email us at: raviinternational01@gmail.com

Phone: Speak to our representative directly by calling: 91-9819030056

Online Form: Fill out online form for a quick response, and we’ll get back to you within 24 hours.