The following are Rotocone vacuum dryer specification, operation and working principle.

Rotocone vacuum dryer specification :

A Rotocone Vacuum Dryer is a type of industrial dryer that is designed for drying heat-sensitive and delicate materials at low temperatures while minimizing the risk of contamination. It is made up of a conical shaped vessel with a jacket for heating or cooling and a rotating agitator that helps in even drying.

The following are some typical – Rotocone Vacuum Dryer specification(s):

- Capacity: The capacity of a Rotocone Vacuum Dryer can range from a few liters to several thousand liters, depending on the size and application.

- Material of construction: The vessel and agitator of a Rotocone Vacuum Dryer can be made of various materials, including stainless steel, mild steel, and other alloys.

- Operating temperature: The operating temperature of a Rotocone Vacuum Dryer can range from ambient to 150°C or higher, depending on the specific application.

- Operating pressure: The operating pressure of a Rotocone Vacuum Dryer can range from atmospheric pressure to a vacuum of 710 mm Hg or more.

- Heating/cooling media: A Rotocone Vacuum Dryer can be designed to use various heating/cooling media, such as hot water, steam, hot oil, or chilled water.

- Agitation speed: The agitator of a Rotocone Vacuum Dryer can rotate at speeds ranging from 5 to 25 RPM, depending on the size and application.

- Control system: A Rotocone Vacuum Dryer can be equipped with a variety of control systems, such as manual, semi-automatic, or fully automated PLC-based controls.

- Optional features: Depending on the application, a Rotocone Vacuum Dryer can be equipped with various optional features, such as a condenser, a dust filter, a solvent recovery system, and a discharge valve for easy removal of the dried product.

Rotocone vacuum operation :

Rotocone vacuum dryer is a type of rotary dryer that is used for drying of materials under vacuum. It is particularly useful for drying heat-sensitive materials, as the low pressure inside the dryer reduces the boiling point of water and other solvents, allowing for gentle drying at lower temperatures.

Here are the basic steps involved in the operation of a Rotocone vacuum dryer:

- Loading: The material to be dried is loaded into the dryer through the charging port. The dryer is typically filled to about 50-60% of its total volume, to allow for proper mixing and tumbling of the material during the drying process.

- Heating: The heating system of the dryer is then activated, typically using steam or hot water as the heating medium. The heat is transferred to the material through the dryer’s rotating cone and jacketed shell, causing moisture to evaporate.

- Vacuum: Once the material is heated, the vacuum system of the dryer is activated, creating a low-pressure environment inside the dryer. This helps to reduce the boiling point of any remaining solvents or moisture, allowing them to evaporate more easily.

- Cooling: After the drying process is complete, the cooling system of the dryer is activated, typically using cold water or air. This cools down the material and prevents any further evaporation of moisture or solvents.

- Unloading: Finally, the dried material is removed from the dryer through the discharge port. The discharge process can be manual or automated, depending on the specific design of the dryer.

Overall, the Rotocone vacuum dryer is a highly efficient and effective method for drying heat-sensitive materials. Its ability to operate under vacuum reduces the need for high temperatures, allowing for gentler drying and preservation of the material’s quality.

Rotocone vacuum working principle :

A Rotocone Vacuum Dryer (RCVD) is a type of drying equipment used for the drying of materials in industries such as pharmaceuticals, food processing, and chemical engineering. The dryer works on the principle of conduction, convection, and radiation.

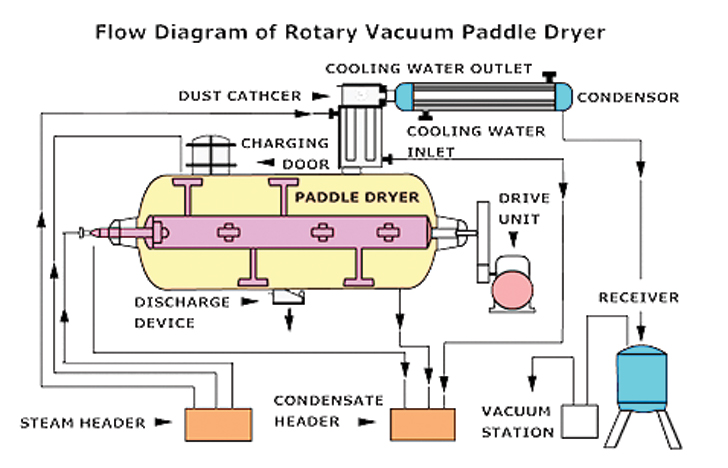

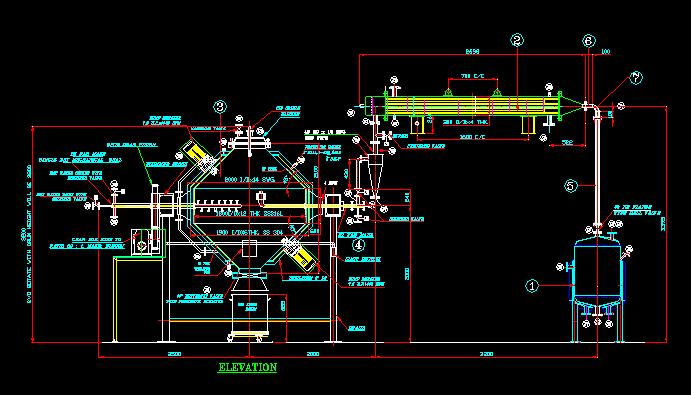

The RCVD consists of a jacketed cylindrical shell with a conical bottom and top. The shell is supported on a sturdy frame and rotated by a motor. The conical bottom and top are connected to a vacuum pump and a heating source respectively. The material to be dried is loaded into the dryer through the top, and the cone is sealed with a lid.

Once the material is loaded, the shell is rotated, and the vacuum pump is started to create a vacuum inside the dryer. The vacuum helps to reduce the boiling point of the solvent present in the material, which helps in the efficient removal of moisture.

The conical shape of the bottom promotes uniform mixing and tumbling of the material, which ensures proper drying. The heating source in the top provides heat to the material, and the jacketed shell helps to maintain the temperature uniformity throughout the dryer.

The dryer’s working principle is based on the transfer of heat energy from the heating source to the material, which causes the moisture in the material to evaporate. The evaporated moisture is then removed by the vacuum, which is created inside the dryer.

Once the drying is completed, the vacuum is released, and the dried material is discharged from the bottom of the dryer. The RCVD is a highly efficient drying equipment that helps to reduce drying time and increase product quality.

Email: For detailed inquiries or quotes, email us at: raviinternational01@gmail.com

Phone: Speak to a representative directly by calling: 91-9819030056

Online Form: Fill out below contact form for a quick response, and we’ll get back to you within 24 hours.