Ravi International – Fluid Bed Dryers, offer a wide range of benefits depending on their unique design. Below are the main Fluid bed dryer advantages and disadvantages in the pharmaceutical, bulk drug, food and chemical industries. (watch video)

Fluidized bed drying (FBD) has found many applications for drying granular solids in the food, pharmaceutical and agriculture industries. For drying of powders in the 50–2000 µm range, Fluid Bed Dryer competes successfully with other more traditional drier types, e.g. rotary, tunnel, conveyor, continuous tray, etc.

fluid bed dryer advantages and disadvantagesFluid Bed Dryer Advantages & Disadvantages

Main Advantages

• Machine has ability to process large volume of fluids.

• Fluid Bed Dryers ensures Fast and Homogeneous Drying

• Fluid Bed Dryer is suitable for non sticky & Heat Sensitive Products

• Fluid Bed dryer are efficient to dry material at low temperature.

• Handling of FBD is easy and less labour intensive

• Machine comes in wide range of capacities & sizes.

• Fluid Bed Dryer comes with Standard design & can also design according to clients requirement

• Fluid Bed Dryer has low maintenance cost hence, reduces downtime

• No hot spots on the final products

• Machine is suitable for both Continuous & batch material processing

Main Disadvantages

• Particle commutation (break up) is common.

• A possibility of fine product loss.

• Non uniform flow pattern. (difficult to predict)

• In Fluid Bed – chances of electrostatic build up may be high

• In Fluid Bed – drying sticky material is very difficult

• Due to complexity of fluid bed dryer behavior, there are often difficulties in attempting to scale-up from smaller scale to industrial units.

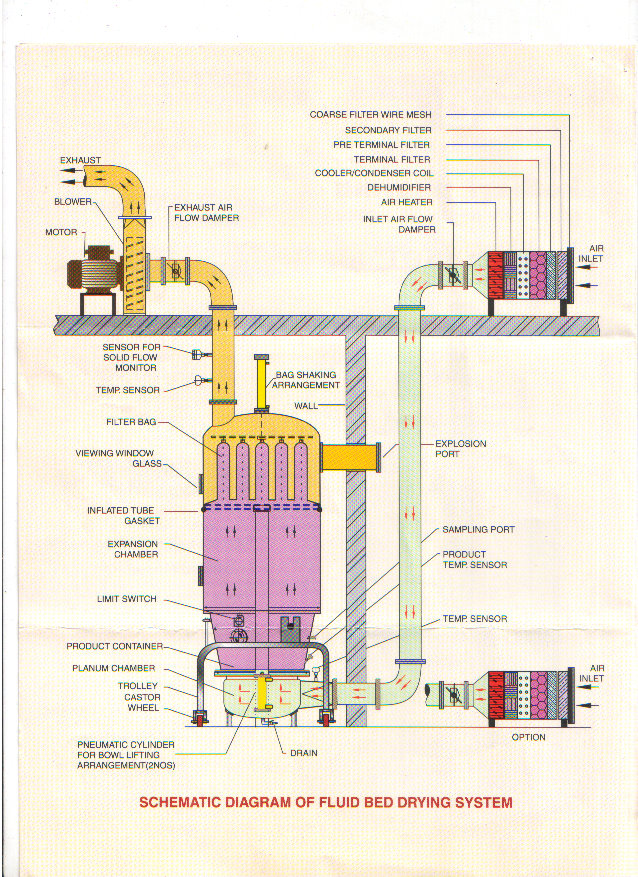

Fluid bed dryers use an upward flow of heated air and mechanical shaking to create a fluid effect in powders. Fluid bed drying has been successfully employed in the production of commercial dried yeast. The advantages of fluid bed drying include low investment and maintenance costs, large-scale continuous production, lower air temperatures than spray drying and a relatively short drying time compared to freeze drying and vacuum drying. However, non-granular samples cannot be dried using fluid bed drying. Therefore, it is essential to encapsulate microorganisms in a granular carrier before subjecting them to fluid bed drying.

Email: For detailed inquiries or quotes, email us at: raviinternational01@gmail.com

Phone: Speak to a representative directly by calling: 91-9819030056

Online Form: Fill out below contact form for a quick response, and we’ll get back to you within 24 hours.