✅ Continuous Fluidized Bed Dryer (CFBD) – Detailed Overview

A Continuous Fluidized Bed Dryer (CFBD) is an industrial drying system widely used in pharmaceutical, chemical, food, and mineral industries. It offers consistent, efficient, and continuous drying of particulate materials.

🔑 Key Features – Continuous Fluidized Bed Dryer

- Continuous operation – material enters one side, dries in the fluidized zone, and exits on the other side without interruption.

- Uniform drying – hot air fluidizes particles ensuring uniform heat transfer.

- Efficient moisture removal – reduces drying time compared to batch systems.

- Controlled environment – adjustable parameters like air temperature, flow rate, and residence time.

- Scalability – suitable for small pilot units to large industrial plants.

✅ Working Principle – Continuous Fluidized Bed Dryer

- Material Feeding: Wet material (granules, powders, crystals) is fed continuously into the dryer.

- Fluidization Zone:

- Hot air passes upward through the bed of particles.

- The air flow lifts and suspends particles, creating a fluid-like behavior.

- Heat & Mass Transfer:

- Moisture evaporates from the particle surfaces.

- Hot air carries away vaporized moisture.

- Residence Time Control:

- The design ensures each particle stays in the dryer long enough for uniform drying.

- Discharge:

- Dried product exits continuously, typically via a vibrating screen or discharge outlet.

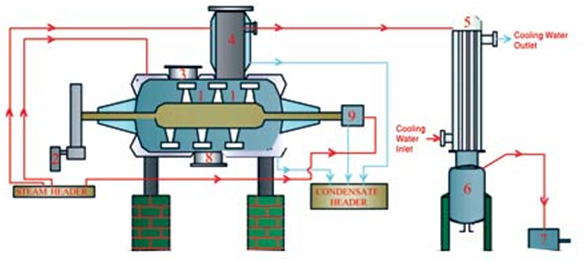

✅ Major Components

- Feed Hopper – supplies wet material.

- Fluidized Bed Chamber – where drying happens.

- Hot Air Blower – provides heated airflow.

- Distributor Plate – ensures even air distribution.

- Moisture Separator – removes entrained moisture particles.

- Discharge System – collects the dried product.

- Control Panel – regulates temperature, air flow, and other parameters.

✅ Applications

- Pharmaceuticals – drying granules, powders, active ingredients.

- Food Industry – drying grains, seeds, snacks, spices.

- Chemicals – drying catalysts, pigments, resins.

- Minerals & ceramics – drying sand, clay, minerals.

✅ Advantages

✔ High thermal efficiency

✔ Consistent product quality

✔ Reduced batch-to-batch variability

✔ Lower energy consumption

✔ Minimal manual intervention

✔ Easily automated and integrated with upstream/downstream processes

✅ Design Considerations

- Airflow rate and velocity

- Temperature uniformity

- Particle size distribution

- Bed height and length

- Moisture content before and after drying

- Product fragility (avoid attrition or breakage)

✅ Safety & Maintenance

- Ensure proper airflow to avoid dead zones or overheating.

- Install sensors for temperature and humidity monitoring.

- Regular cleaning to prevent clogging or contamination.

- Safety interlocks to prevent dry running or overheating.

✅ Comparison: Continuous FBD vs Batch FBD (and Related Variants)

| Feature / Parameter | Continuous Fluidized Bed Dryer (CFBD) | Batch Fluidized Bed Dryer (Batch FBD) | Top-Spray / Bottom-Spray FBD (Granulation FBD) |

|---|---|---|---|

| Operation Mode | Continuous | Batch | Batch or semi-continuous |

| Typical Applications | Large scale drying of powders, granules | Small to medium batch drying | Granulation, coating, drying, mixing |

| Material Feed & Discharge | Constant feed and discharge | Manual or periodic | Intermittent, with spray nozzles |

| Control of Moisture | Precise, uniform drying | Less uniform, dependent on batch size | Controlled, especially for granules or coated products |

| Process Efficiency | High | Moderate | Moderate to high depending on setup |

| Heat Transfer | Excellent fluidization heat transfer | Good but less uniform | Controlled through spray distribution |

| Automation | High | Limited | Moderate to high, depending on process |

| Scale of Operation | Industrial, large | R&D, small-medium scale | Medium scale, specialized products |

| Maintenance Complexity | Moderate | Simple but requires batch cleaning | Higher due to spray nozzles and maintenance |

| Energy Use | Efficient | Less efficient | Moderate to high depending on granulation load |

| Footprint | Compact for large volumes | Smaller footprint | Medium footprint with additional spray components |

| Product Quality | Uniform, low degradation | Variability across batches | Excellent for uniform granules, coatings |

| Process Flexibility | Less flexible (optimized for one product at a time) | High, can handle multiple products | Moderate, suited for coated or granulated products |

| Limitations | Needs continuous feed and robust process control | Downtime between batches, inconsistent quality | Sensitive to feed properties, nozzle clogging, higher complexity |

| Cost | Higher initial investment | Lower capital cost | Moderate to high depending on granulation requirements |

✅ Key Differences Explained

1. Operation Mode

- CFBD is best for uninterrupted, high-throughput drying operations.

- Batch FBD suits smaller volumes and allows multiple formulations in separate batches.

- Top/Bottom Spray FBDs are specialized for processes like granulation or coating where spray distribution is key.

✅ 2. Product Types

- CFBD excels in drying powders, crystals, and granules with minimal degradation.

- Batch FBD is more suited for occasional drying runs, smaller-scale batches, or products that need frequent changeovers.

- Spray-based FBDs are ideal for producing coated granules, tablets, or uniform agglomerates.

✅ 3. Process Control

- CFBD allows precise control over air flow, temperature, and residence time — crucial for sensitive materials.

- Batch FBD relies on operator control; variability may occur depending on loading and time.

- Spray FBDs require control over spray rate, droplet size, and air distribution to maintain quality.

✅ 4. Maintenance & Cleaning

- CFBD has continuous operation but requires cleaning schedules and filter maintenance.

- Batch FBD requires more manual cleaning after each batch but is simpler to operate.

- Spray FBDs need maintenance of nozzles, pumps, and filters, increasing operational complexity.

✅ 5. Suitability by Industry

✔ CFBD → Large pharmaceutical, chemical, and food production lines

✔ Batch FBD → R&D labs, pilot plants, small-scale production

✔ Spray FBD → Pharmaceutical granulation, food coating, specialty powders

✅ When to Choose Which?

| Scenario | Recommended Dryer |

|---|---|

| High-volume continuous drying | CFBD |

| R&D or low-volume production | Batch FBD |

| Coating, granulation, or specific texture formation | Top/Bottom Spray FBD |

| Uniform moisture content with automated control | CFBD |

| Multiple products with frequent changeover | Batch FBD |

| Producing pellets or coated materials | Spray FBD |